Auger Boring

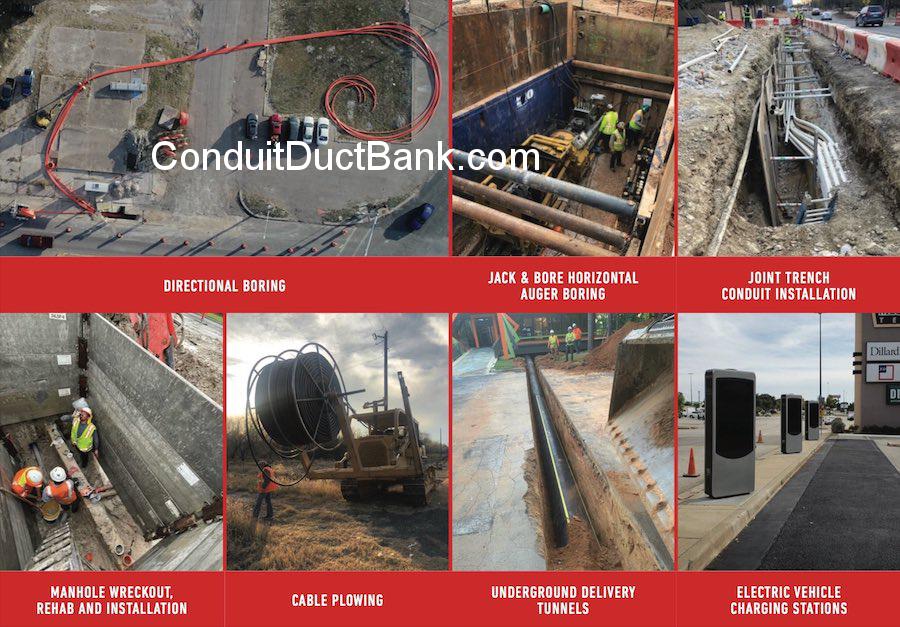

Horizontal Auger Boring is a term used in the trenchless underground construction industry that has several similar names and applications: Road Auger Boring, Horizontal Earth Boring, Guided Auger Boring, Jack and Bore, Pipe Jacking, Pipe Ramming, Sliplining and Concrete Box Jacking.

In general auger boring is more precise that directional drilling and its used to place pipes on precise grade and under surfaces that can’t be disturbed like roads and railroads.

Auger Boring:

A technique for forming a bore hole from a drive pit to a reception pit, by means of a rotating cutting head. Spoil is removed back to the drive shaft by helically wound auger flights rotating in a steel casing. The auger boring equipment may have limited steering capability.

Conduit Duct Bank Auger Bore | Horizontal Auger Boring Setup

Conduit Duct Bank Auger Bore | Horizontal Auger Boring Setup

Horizontal auger boring (HAB), also known as horizontal earth boring or jack and bore, may be the best underground option for drilling lengths up to 500 feet and diameters up to 60 inches in variety of soil conditions. Horizontal auger boring can be used to install pipes in changeable ground conditions and, in many cases, has lower overall costs compared to other trenchless methods.

The Horizontal auger bore process uses a revolving cutting head that is located at the leading end of an auger assembly to excavate the soil. Common practice is to jack the steel casing through the excavated hole as it is being bored. The spoil is then transported back to the shaft area by the rotation of the helical auger flights within the steel pipe casing.

Auger boring machines come in different sizes and capacities. Ground conditions usually dictate how powerful of an auger machine is needed. If the ground is sandy or heavy clay, more force is required.

Conduit Duct Bank Auger Bores | Horizontal Auger Bore Pushing Casing

Conduit Duct Bank Auger Bores | Horizontal Auger Bore Pushing Casing

Auger Machine:

The auger boring machine is used to drill earth horizontally by means of a cutting head and auger or other functionally similar device. The machine may be either cradle or track type.

Horizontal auger boring has been used to install utilities for decades. The process has changed over the years as the technology has changed yet auger boring is one of the most cost effective methods of installing utilities. It is considered the first trenchless pipe installation method used by the construction industry.

Auger boring machines can drill in a variety of soil conditions. Clays, sand and shale can be drilled with the basic equipment. Rock can be auger drilled as well but requires special equipment.

In cases where the ground is unstable, a wash-over pipe, or casing, can be pushed through the borehole to prevent the collapse of the hole walls. Some systems use a dual pipe exclusively.

Conduit Duct Bank Auger Boring | Horizontal Auger Boring Railroad Crossing

Conduit Duct Bank Auger Boring | Horizontal Auger Boring Railroad Crossing

Railroad Auger Boring Services

Railroad Auger Boring Services

Horizontal auger boring (also known as auger boring, jack and bore, and various other names is a underground construction method performed by boring from a launch shaft to a receiving shaft. A steel encasement of the desired diameter is installed as the bore and hole advance. A rotating cutting head is attached to helically wound auger flights, which rotate to drive the cutting head and carry the excavated spoil back to the launch shaft. The auger boring process is used from as small as a 6